Walk into any warehouse, workshop, or production space, and you’ll probably spot at least one weighing scale quietly doing its job. It might be checking incoming stock, weighing finished products, or helping staff keep records accurate. While all scales serve the same basic purpose, not all are built for the same tasks. Two of the most common options are platform scales and bench scales, and knowing the difference can save time, effort, and frustration.

At first glance, choosing a scale might seem straightforward. But when weight ranges, space limits, and daily use come into play, the right choice becomes clearer. Understanding how these two scale types are used in real workplaces helps make that decision easier.

What Platform Scales Are Typically Used For

Platform scales are designed for weighing heavier or bulkier items. They usually sit directly on the floor and have a large, flat surface for placing items. Pallets, drums, crates, and heavy cartons are common loads. These scales are often found in warehouses, freight depots, farms, and manufacturing plants where moving large goods is part of daily work.

Because they sit low to the ground, platform scales make it easier to load items using pallet jacks, forklifts, or trolleys. There’s no need to lift heavy goods by hand, which helps reduce strain and workplace injuries. The large surface also means items don’t need to be perfectly positioned to get an accurate reading.

Another benefit is durability. Platform scales are built to handle tough environments, including dusty floors, regular movement, and heavy use. They are usually made with solid frames and strong load-bearing components, making them suitable for long shifts and repetitive weighing tasks.

read more : https://celebvalues.com/

Where Bench Scales Come In

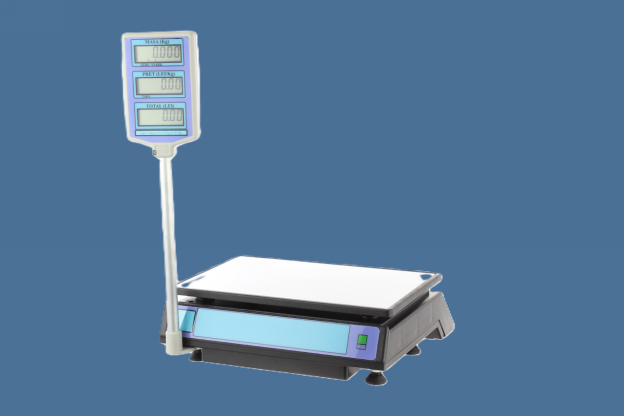

Bench scales are smaller and designed to sit on workbenches, counters, or tables. They are commonly used for lighter items that require frequent, quick weighing. You’ll often see them in packing areas, food prep spaces, laboratories, or retail backrooms.

These scales are ideal when staff need to weigh items at waist height without bending or lifting heavy loads. Bench scales are easy to move, quick to set up, and simple to operate. Because they handle smaller weights, they often offer more detailed readings, which can be useful for portioning, counting, or quality checks.

Their compact size also makes them suitable for tighter spaces. In smaller workplaces or crowded production areas, bench scales fit neatly into existing setups without needing extra floor space.

Size, Capacity and Daily Workflow

One of the biggest differences between these two scale types is capacity. Platform scales are built to handle much higher weights, often several hundred kilograms or more. Bench scales usually support lighter loads, making them better suited for boxes, components, or packaged goods.

The choice often comes down to how items move through the workspace. If goods arrive on pallets or are too heavy to lift safely, a floor-based scale makes sense. In many warehouses, platform scales become part of the natural flow, allowing items to be weighed as they arrive or before they are dispatched.

On the other hand, if weighing happens at a workstation during packing, sorting, or assembly, a bench scale fits better. Staff can weigh items without interrupting their workflow or needing additional equipment to move goods around.

Accuracy and Ease of Use

Both scale types are accurate when used correctly, but they shine in different ways. Platform scales focus on stability and strength, ensuring reliable readings even with uneven or bulky loads. Bench scales, which handle smaller weights, often provide finer increments, which is useful for detailed work.

Ease of use also matters. Platform scales are often paired with remote displays mounted on walls or stands, making readings easy to see from a distance. Bench scales usually have the display built in, right at eye level, making them quick to read during fast-paced tasks.

Neither option is “better” overall—it’s about matching the tool to the job.

Space and Safety Considerations

Space plays a big role in deciding between the two. Platform scales require floor space and clear access for equipment like pallet jacks. In return, they reduce manual lifting and improve safety when handling heavy goods.

Bench scales take up very little room but require staff to lift items onto the scale. This is fine for lighter goods but not practical for larger loads. Choosing the wrong scale type can lead to awkward handling, slow processes, or safety concerns over time.

Making the Right Choice

When deciding between platform and bench scales, consider what is being weighed most often, how heavy those items are, and where the weighing occurs. Many workplaces actually use both, placing each scale where it fits best in the workflow.

The right scale supports staff, speeds up tasks, and reduces errors. It should feel like a natural part of the workspace rather than an obstacle.

Final Thoughts

Both scale types play an important role across Australian industries. Large, floor-based scales support heavy-duty tasks, while smaller counter-based units handle everyday weighing with ease. The key is understanding how each one fits into real-world use and choosing the option that supports your team’s daily work.

Whether you’re handling pallets or parcels, selecting the right equipment helps keep operations smooth, accurate, and safe. For expert advice and reliable weighing solutions across Australia, Meltrons Australia supplies both heavy-duty options and precise bench scales, backed by local knowledge and industry experience.