Why Corrosion Matters in Mechanical Parts

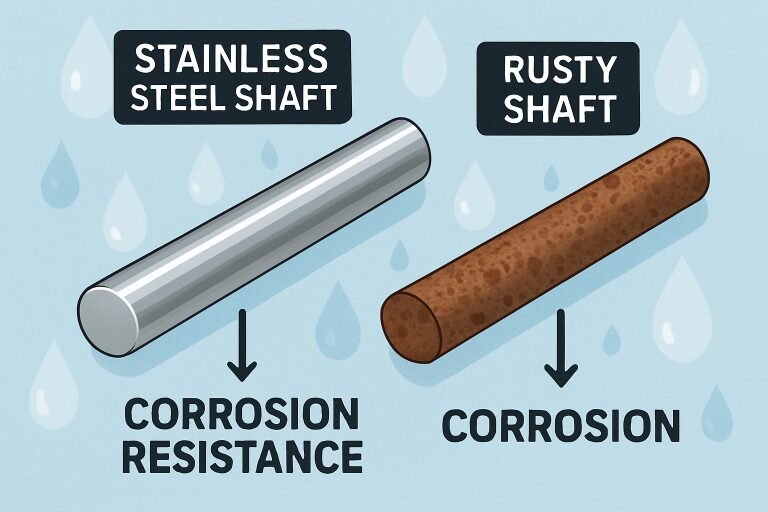

Corrosion presents one of the greatest threats to the reliability and operational lifespan of rotating and structural components, particularly shafts. Continuous exposure to moisture, salt, industrial chemicals, or fluctuating environmental conditions can trigger rust and degradation. For systems that require consistent performance and safety, such vulnerabilities can mean higher operating costs, shorter equipment lifespans, and even catastrophic failure if left unchecked. This is why corrosion-resistant materials such as stainless steel are vital, as they reduce the risk of breakdowns and ensure continuity in critical operations.

Selecting stainless steel, specifically 316 grade, offers exceptional resistance to the most aggressive environments. The SS 316 material properties demonstrate excellent resilience against harsh marine conditions, chlorides, and industrial chemicals, making it an industry benchmark for performance and longevity in shaft applications.

The Science Behind Stainless Steel’s Corrosion Resistance

The remarkable corrosion resistance of stainless steel, especially austenitic varieties like 316 and 316L, lies in its chemistry and structure. The key is a high chromium content—typically above 16%—that spontaneously forms a thin, durable oxide layer at the surface of the metal. This passive layer acts as a shield, separating the underlying steel from harmful elements. Unlike coatings or platings, this layer is self-healing: if it’s scratched or compromised, it reforms quickly in the presence of oxygen. As a result, stainless steel can withstand continuous attack from water, salt, cleaning agents, and acidic substances with minimal loss of integrity.

How to Select the Right Stainless Steel Alloy

Material selection is key to maximizing shaft performance in corrosive environments. Grades like 304, 316, and 316L each have strengths. Grade 304 resists oxidation and acids but may be vulnerable to chloride attack. For harsh chemicals or marine settings, alloys with molybdenum, like 316 or 316L, offer better protection. Consider media, temperature, and cleaning frequency to choose the right alloy for durability and compliance. Industry standards like ASTM and ISO give detailed guidance, and consulting datasheets and resources help ensure optimal performance.

Key Applications Across Industries

Corrosion-resistant stainless steel shafts are indispensable across many fields. In the marine industry, complete immersion in seawater and exposure to salty air demand materials that will not degrade quickly. Food and beverage processors need non-reactive, sanitary surfaces to avoid contamination and ensure regulatory compliance. Medical device manufacturers rely on stainless steel for its biocompatibility—it won’t rust or leach substances that can interfere with sterilization or patient safety. Even water treatment facilities and chemical plants depend on robust shafts that deliver continuous performance despite aggressive conditions.

Comparing Stainless Steel to Other Shaft Materials

While carbon steel and aluminum are often used for their cost-effectiveness and ease of machining, they do not provide the same level of reliability in demanding environments. Carbon steel is prone to rust and pitting, especially where moisture or chemicals are present, often requiring extra coatings for protection—coatings that can be damaged or wear away. Aluminum offers improved corrosion resistance over steel but lacks the strength and wear resistance required for high-stress shaft applications. Stainless steel, conversely, delivers high strength, impressive corrosion resistance, and a long service life, making it the standard in critical, high-value environments.

Future Trends in Corrosion-Resistant Materials

The evolution of corrosion-resistant materials continues at a rapid pace. Next-generation stainless steels incorporate even higher levels of alloying elements, creating more robust and sustainable options. Advanced surface treatments, such as nano-coatings, are being developed to make standard grades of stainless steel even more impervious to aggressive agents. Ongoing research also explores how hybrid solutions—combining stainless steel with polymers or ceramics—can further extend shaft lifespans while reducing manufacturing costs. As industries face growing expectations for efficiency and sustainability, these innovations promise to make corrosion a less significant constraint on equipment design and performance.